Product list

Catalytic block Position:Home > Catalytic block >

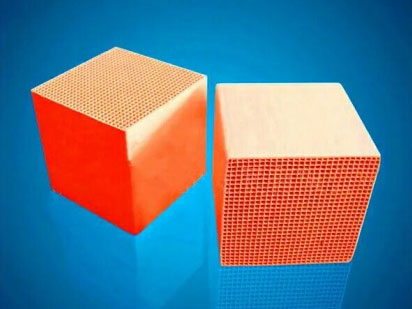

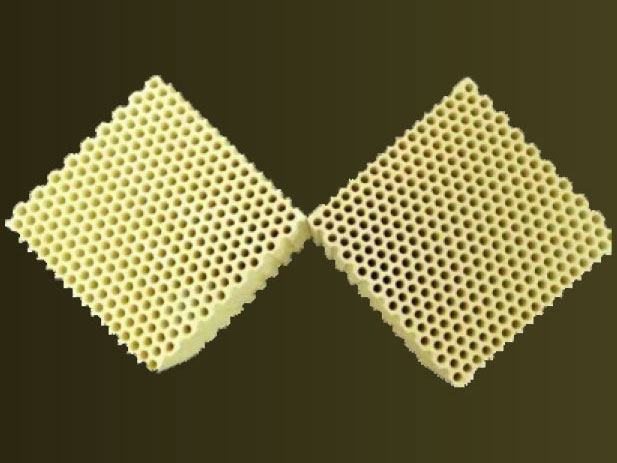

VOC-A-type enamelled charter equipment for high-frequency honeycomb ceramic noble metal (palladium) catalytic block use guide

Our production of VOC-A-type charter charter equipment for high-frequency honeycomb ceramic noble metal catalytic block is used in cordierite high-frequency ceramic honeycomb body as the first carrier, y-al2o3 as the second carrier to precious metals pd, pt The main active ingredient, prepared with a high dispersion uniform distribution method, is a new and efficient various types of industrial waste gas purification catalyst. The catalytic block possesses excellent properties of anti-aging, anti-water vapor, anti-sulfur poisoning and anti-high temperature sintering, and has the dual functions of catalytic combustion and NOX reduction. Nature, the hydrocarbons, phenols in a wide temperature range of combustion into CO2 and H2O have a good catalytic activity. The catalytic block is suitable for the treatment of complex industrial waste gases containing carbon monoxide, aromatic hydrocarbons, phenols and their oxygen-containing derivatives.

First, product performance

1. Wide range of applications, suitable for the treatment of carbon monoxide, hydrocarbons, phenols and their oxygen-containing industrial organic waste gas.

2. Low flow resistance, low reaction temperature, high activity, wide range of airspeed. When the concentration of organic matter (phenol) in the range of 500-9000 mg / m, the space velocity is 15000-30000 h-1 and the reaction gas inlet temperature is 350 ℃ -450 ℃, the purification effect is more than 98%.

3. Good heat resistance, can withstand the short-term impact of 900 high temperature.

4. Service life is generally 1-3, and can be customized according to user requirements.

Second, the scope of application

Enameled wire production of exhaust gas purification treatment, chemical, food, machinery, instrumentation, household appliances, baking paint, insulation materials, color steel manufacturing industry emissions containing aromatics, oxygen and other organic compounds and carbon monoxide poisonous toxic emissions can be applied.

Third, the main specifications and technical indicators

1. shape: square honeycomb body

2. Hole: round, square

3. Carrier specific surface: 20 m2 / g

4. Size: 100x100x50 (40) mm; 49x49x50 mm;

5. Aperture: Round hole: 2.00mm-2.60mm; Square hole: 1.60mm-2.00mm

6. Hole density: 30 / in2 (square), 8 / cm2 (round)

7. Strength: a ≥ 12mpa, b ≥ 4.5mpa.

Fourth, the use of instructions and precautions

1. Before each use of the catalyst (block), must first with no exhaust of fresh air in the 400-500 ℃ temperature range for more than half an hour.

2. When the new catalytic block is used, the preheating temperature of the catalyst is increased to 400 ℃ -500 ℃. If the temperature is reached after the catalyst reaches the temperature of 400 ℃ for half an hour, it can be switched on (absolutely) When the catalytic temperature below 250 ℃ -300 ℃ when the introduction of organic waste gas, or very easy to make the catalyst block poisoning failure and the reactor appears "suffocated" phenomenon.

3. To ensure that the catalytic block is not toxic, not coking under the premise and after the temperature stability of the catalytic case (650 ℃ -750 ℃), in order to reduce energy consumption as much as possible, according to the specific circumstances, , Can be 400-500 ° C temperature range appropriate adjustment of the pre-catalytic exhaust gas preheating temperature.

4. As far as possible to avoid the introduction of significant dust, can effectively prevent the blocking block of the catalytic block.

5. The use of catalytic block The best temperature range: 650 ℃ -750 ℃, try to avoid the catalytic block for a long time above 750 ℃ ??high temperature.

6. The exhaust gas source must be cut off at the time of shutdown, and it is absolutely prohibited to continue to pass the exhaust gas when the catalytic bed is heated and the temperature has been lower than the required preheating temperature.

7. Special remind: enameled wire paint is absolutely prohibited containing halogen compounds, because some of the chemical substances will make the catalytic block poisoning, such as zinc, lead, sulfur and other chemical substances on the catalytic block destructive effect will lead to the catalytic block permanent failure , Can not restore its activity. (Note the quality of paint)

8. According to the specific use of the device, when the catalytic block is used for a long time after the activity may decline, the upper and lower catalytic block can be placed, if necessary, to improve the catalytic bed and exhaust gas preheating temperature.

9. Catalytic block in the course of the use of the latter part of the activity will slowly decline to a certain extent, please contact the company to replace the new catalytic block.

Attached: factory activity test indicators (purification rate ≥ 98% of the ignition temperature and the corresponding concentration)

Our production of VOC-A-type charter charter equipment for high-frequency honeycomb ceramic noble metal catalytic block is used in cordierite high-frequency ceramic honeycomb body as the first carrier, y-al2o3 as the second carrier to precious metals pd, pt The main active ingredient, prepared with a high dispersion uniform distribution method, is a new and efficient various types of industrial waste gas purification catalyst. The catalytic block possesses excellent properties of anti-aging, anti-water vapor, anti-sulfur poisoning and anti-high temperature sintering, and has the dual functions of catalytic combustion and NOX reduction. Nature, the hydrocarbons, phenols in a wide temperature range of combustion into CO2 and H2O have a good catalytic activity. The catalytic block is suitable for the treatment of complex industrial waste gases containing carbon monoxide, aromatic hydrocarbons, phenols and their oxygen-containing derivatives.

First, product performance

1. Wide range of applications, suitable for the treatment of carbon monoxide, hydrocarbons, phenols and their oxygen-containing industrial organic waste gas.

2. Low flow resistance, low reaction temperature, high activity, wide range of airspeed. When the concentration of organic matter (phenol) in the range of 500-9000 mg / m, the space velocity is 15000-30000 h-1 and the reaction gas inlet temperature is 350 ℃ -450 ℃, the purification effect is more than 98%.

3. Good heat resistance, can withstand the short-term impact of 900 high temperature.

4. Service life is generally 1-3, and can be customized according to user requirements.

Second, the scope of application

Enameled wire production of exhaust gas purification treatment, chemical, food, machinery, instrumentation, household appliances, baking paint, insulation materials, color steel manufacturing industry emissions containing aromatics, oxygen and other organic compounds and carbon monoxide poisonous toxic emissions can be applied.

Third, the main specifications and technical indicators

1. shape: square honeycomb body

2. Hole: round, square

3. Carrier specific surface: 20 m2 / g

4. Size: 100x100x50 (40) mm; 49x49x50 mm;

5. Aperture: Round hole: 2.00mm-2.60mm; Square hole: 1.60mm-2.00mm

6. Hole density: 30 / in2 (square), 8 / cm2 (round)

7. Strength: a ≥ 12mpa, b ≥ 4.5mpa.

Fourth, the use of instructions and precautions

1. Before each use of the catalyst (block), must first with no exhaust of fresh air in the 400-500 ℃ temperature range for more than half an hour.

2. When the new catalytic block is used, the preheating temperature of the catalyst is increased to 400 ℃ -500 ℃. If the temperature is reached after the catalyst reaches the temperature of 400 ℃ for half an hour, it can be switched on (absolutely) When the catalytic temperature below 250 ℃ -300 ℃ when the introduction of organic waste gas, or very easy to make the catalyst block poisoning failure and the reactor appears "suffocated" phenomenon.

3. To ensure that the catalytic block is not toxic, not coking under the premise and after the temperature stability of the catalytic case (650 ℃ -750 ℃), in order to reduce energy consumption as much as possible, according to the specific circumstances, , Can be 400-500 ° C temperature range appropriate adjustment of the pre-catalytic exhaust gas preheating temperature.

4. As far as possible to avoid the introduction of significant dust, can effectively prevent the blocking block of the catalytic block.

5. The use of catalytic block The best temperature range: 650 ℃ -750 ℃, try to avoid the catalytic block for a long time above 750 ℃ ??high temperature.

6. The exhaust gas source must be cut off at the time of shutdown, and it is absolutely prohibited to continue to pass the exhaust gas when the catalytic bed is heated and the temperature has been lower than the required preheating temperature.

7. Special remind: enameled wire paint is absolutely prohibited containing halogen compounds, because some of the chemical substances will make the catalytic block poisoning, such as zinc, lead, sulfur and other chemical substances on the catalytic block destructive effect will lead to the catalytic block permanent failure , Can not restore its activity. (Note the quality of paint)

8. According to the specific use of the device, when the catalytic block is used for a long time after the activity may decline, the upper and lower catalytic block can be placed, if necessary, to improve the catalytic bed and exhaust gas preheating temperature.

9. Catalytic block in the course of the use of the latter part of the activity will slowly decline to a certain extent, please contact the company to replace the new catalytic block.

Attached: factory activity test indicators (purification rate ≥ 98% of the ignition temperature and the corresponding concentration)

| Benzene | 4g/m3 | 240℃ |

| Acetic acid | 5g/m3 | 300℃ |

| Cyclohexanone | 4g/m3 | 220℃ |

| Ethyl acetate | 5-6g/m3 | 300℃ |

| Xylene | 4g/m3 | 220℃ |

| Phenol | 10g/m3 | 280℃ |

| Toluene | 4g/m3 | 220℃ |

| Acetone | 5g/m3 | 280℃ |

| Positive ethanol 4 | 4g/m3 | 180℃ |